Tackling Skilled Labour Shortage in Manufacturing through AI

Our venture Deltia has just raised €4.5M in seed funding towards modernising assembly lines with computer vision and AI.

Our venture Deltia.ai has just announced the completion of a EUR 4.5 million seed funding round today. The funds will support their mission to modernise assembly lines with computer vision and AI, addressing the increasing demand for skilled production workers.

The financing round was led by Berlin-based early-stage investor Cavalry Ventures, and we at Merantix Merantix joined as an existing investor. Additionally, Deltia.ai has garnered support from a series of prominent investors with industry expertise, including Nico Peters and Willi Tscheschner (both founders of Signavio), Max Viessmann (CEO of the Viessmann Group), Walter Kortschak (Firestreak Ventures), Christian Dahlen, Edward Grefenstette (Google DeepMind), Robin Capital, and Combination Ventures.

I sat together with the co-founder and CEO, Max Fischer to talk about their product, privacy concerns, achievements and future plans.

Can you describe Deltia’s technology and how it’s currently being used?

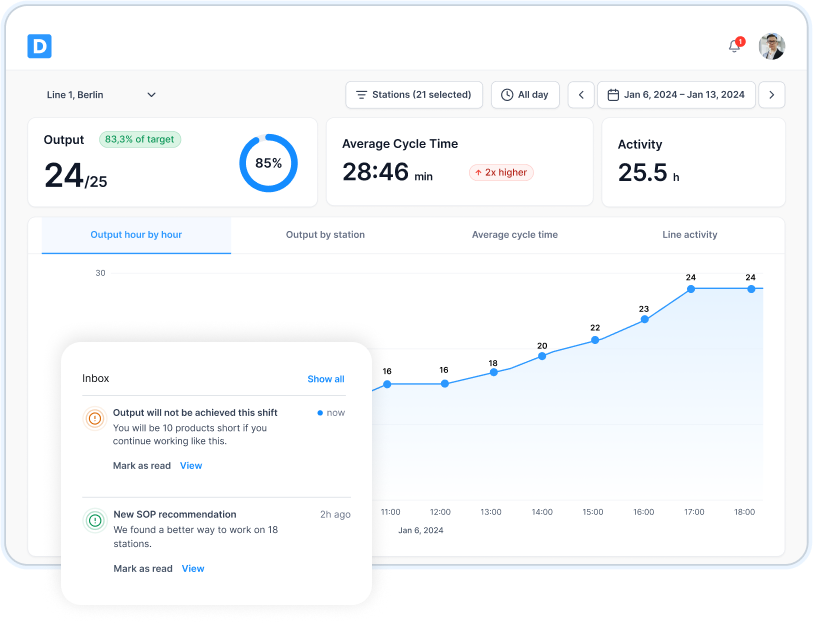

We use computer vision technology to digitize industrial processes to provide visibility into what is happening on the shop-floor. We focus on digitizing manual process such as assembly processes or machine setup - our technology can also be used to track machine processes or material flow. Our customers are using Deltia to identify issues in real-time, identify improvement potential, and facilitate training of new employees.

What are some of the biggest challenges right now in manufacturing, and how is Deltia working to help solve those problems?

A big problem is the lack of skilled workers for manufacturing companies. In Europe, due to the demographic development, many experienced workers are retiring in the next 5-10 years, taking with them a lot of know-how. In the US, a lot of new production facilities are being built up, requiring a lot of new workers to be trained in working in factories. We mitigate this problem in three steps: first is to digitize manual work to drive efficiency and document best-practices. The second step is to assist and train less experienced workers in doing complex task. The last step is to identify automation potential and train robots to work alongside humans on the shop-floor.

How can we ensure that Europe can stay competitive when it comes to manufacturing?

Europe needs to leverage digital technology to drive efficiency across all functions to stay competitive to Asian and US companies. It will be hard to compete in high energy intensive or mass-market areas due to higher energy prices and often smaller scale due to a more fragmented market when compared to US or Asia. Europe needs to focus on the areas where it can stay competitive and combine engineering excellence to drive product innovation with manufacturing excellence to drive down cost.

Data security is surely a huge priority for your clients and their personnel? How does Deltia’s technology work to ensure privacy?

Privacy and security are very important topics for us. Cameras are often associated with surveillance since they enable live monitoring. We use cameras in a different way - we use them as a sensor. Video streams are automatically analysed on a PC in the factory to generate statistics such as cycle times or walking routes. Raw video footage is then immediately deleted again. In some cases, it is interesting to save a few excerpt video snippets (<5% of the videos) for training and documentation purposes - these videos are anyonmised, meaning that we completely cut the person out of the video.

Automation is a controversial topic, particularly when it comes to the threat of job losses. How do you respond to those concerns when you hear them?

Automation is not a choice, but a necessity. The problem of a shortage of skilled workers will only become more and more pressing in the future, requiring us to automate more and more tasks. Factories are the backbone of our society building everything we consume from food, machines, cars, electronics, wind-turbines or solar panels. If we don’t automate, we won’t be able to build the products that are required to sustain our standard of living and help us to face big challenges such as making our economy carbon neutral.

What are your plans for the future and how are you going to use this new investment?

With the newly acquired funding, we aim to accelerate customer onboarding, enhance AI capabilities to also support automated machining processes, and integrate data from customer IT systems, including ERP, to offer more comprehensive insights into manufacturing processes. We will also bolster our go-to-market team, aiming to expand our reach to dozens more factories within the next 18–24 months.

In 10 years time, what do you think manufacturing looks like in Europe, and where does Deltia fit into the equation?

We believe that factories in the future will not be fully automated, but humans will work alongside machines and robots. In ten years, most factories will leverage AI to control and continuously optimize manufacturing operations, all assets will be fully connected, repetitive task will be automated by robots whilst humans focus on complex task, and workers will be assisted by AI in executing and learning new tasks. Deltia‘s place is being the co-pilot for shop-floor worker and a software platform to teach robots executing tasks.

More information on Deltia can be found on their website and the latest updates on their Linkedin profile.